Choosing the right CAD solution is one of the challenges in manufacturing. Some of the common choices when looking for the right tools are: 2D vs. 3D design and custom vs. repeat design. We are going to examine both those choices and explain why we at PathFinder3D have chosen SolidWorks as the best option currently out there.

There is a class of software tools created mostly for the cabinet manufacturing industry that work well for repeat work of box design type products. With repeat work you want kitchen upper #1 to be just like kitchen upper #2 except with a few changes in dimensions and with a different finish. On the other end of the spectrum you get jobs that need one-of-a-kind custom work that will never be repeated and is often highly complex in design. Historically shops have used a flexible CAD program like AutoCAD for custom, one-off designs. In the store fixtures industry many jobs have a mix of custom and repeat work. For this reason many shops buy 2 or more CAD software packages and use one tool for repeat work and yet another one for custom work. The downfall to this approach is that creating the design using several different CAD packages leads to a lot of duplicate work, is error prone and makes the whole design to manufacturing process much more time consuming and complex then it needs to be. We at PathFinder3D believe using multiple CAD packages for a single job is not a valid option. We also don't think you should have to choose between excellence in doing repeat work and excellence in doing custom work. The right CAD tool should do both well. With this criteria in mind we went searching for the right CAD solution and have arrived at SolidWorks as the best answer currently out there.

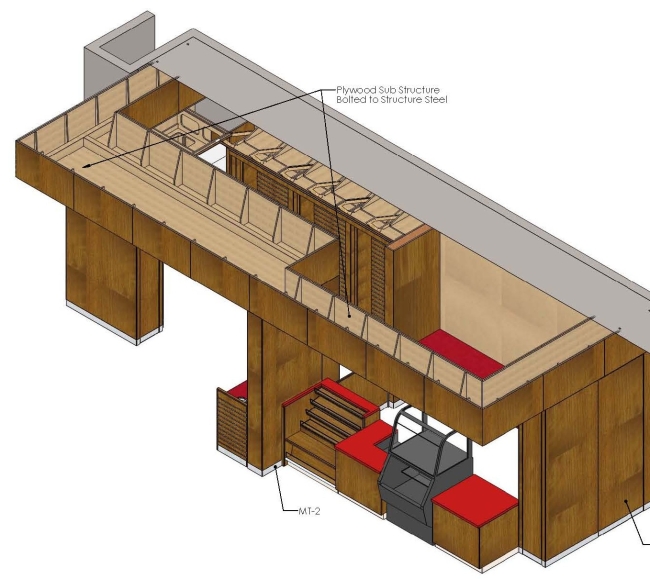

SolidWorks is used worldwide for designing all manner of products so it is not hard to make the case that it is a good tool for custom work. The screen shot below is only one example of many that we could show you. A common misconception that we should clear up is that although SolidWorks is a parametric design tool, you don't have to design parametrically. You can use parametric constraints as much or as little as you like. We should also point out that PathFinder3D does not constrain you to any predefined cabinet construction techniques. You can use all the power of SolidWorks in whatever way you choose to come up with your model. The value of PathFinder3D is that it reduces the time, error and complexity involved with moving custom, high end designs, like the one in the screen shot below, from a model in SoldWorks to the manufacturing floor.

SolidWorks has another powerful feature called "Weldments" that, among other uses, make adding trim

or

moulding a point and click operation. See the video for a demonstration

There are many more features that make SolidWorks a competitive option for repeat designs. As we have time we will add more videos to demonstrate these features.

The 2D vs. 3D debate is probably even now a debate of the past. The ability to visualize the product and design it as you visualize has obvious advantages. Unless you are designing boxes, 3D design gives you a definite edge over 2D. Many of the challenges facing 3D CAD programs of the past, such as computation speed, non-intuitive user interfaces and bottom up only design have since been overcome. So if you have been told that 3D design is too difficult and shouldn't be used for your particular industry then take a second look. SolidWorks does an excellent job of 3D visualization and people throughout the world have found it's user interface to be easy to learn and powerful to master.

We are aware that there are other CAD solutions out there that have 3D parametric design capabilities and also handle custom work. Autodesk Inventor is one such solution. So far we have been disappointed with the user interface and limited features of Inventor and other similar products. We stand ready to change our opinions though. In fact, we have in the past. The predecessor to PathFinder3D was originally an add-in for Autodesk Mechanical Desktop. When Autodesk discontinued development on Mechanical Desktop and encouraged users to switch to Inventor, we compared Inventor with what was available at that time and jumped ship to SolidWorks. It has proved to be a good move. The industry is always changing so if you think we are missing out on an up and coming CAD product that will outpace SolidWorks then please let us know. We are in the business of taking the best CAD products on the market and bridging the gap between the model and the manufacturing floor.